White Paper | April 2025

Challenges in the processing of high-viscosity 2K adhesives with a manual dispenser

Author: Dipl.-Ing. Wolfgang Wulff, Head of Application Engineering • European Adhesive Engineer • European Welding Engineer

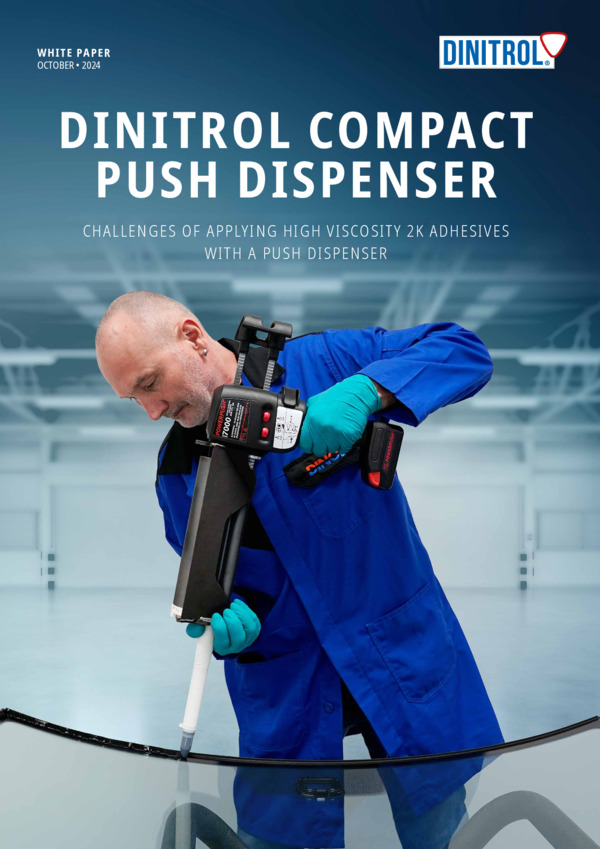

DINITROL Compact Push Dispenser

The use of 1K moisture curing adhesives is limited when

thick-film bonding with a high adhesive content is

required. This is due to the fact that the moisture must dif-

fuse from the outside to the inside in order for the adhesive

to cure. The curing speed decreases with increasing curing,

which means long service lives until the adhesive bond can

be fully stressed. If the accessibility of air humidity through

narrow gaps (ratio of gap width to depth) is small and only

on one side, it can happen that an adhesive in the core

does not cure at all. In these cases, it is advisable to use a

2-component adhesive that is independent of air humid-

ity. A secure bond is achieved in a defined time and

downtimes are reduced.

The processing of 2 components and their homogeneous

mixing is somewhat more complicated. This article describes

the challenges and problem solutions in the development

of the DINITROL 2K COMPACT PUSH DISPENSER