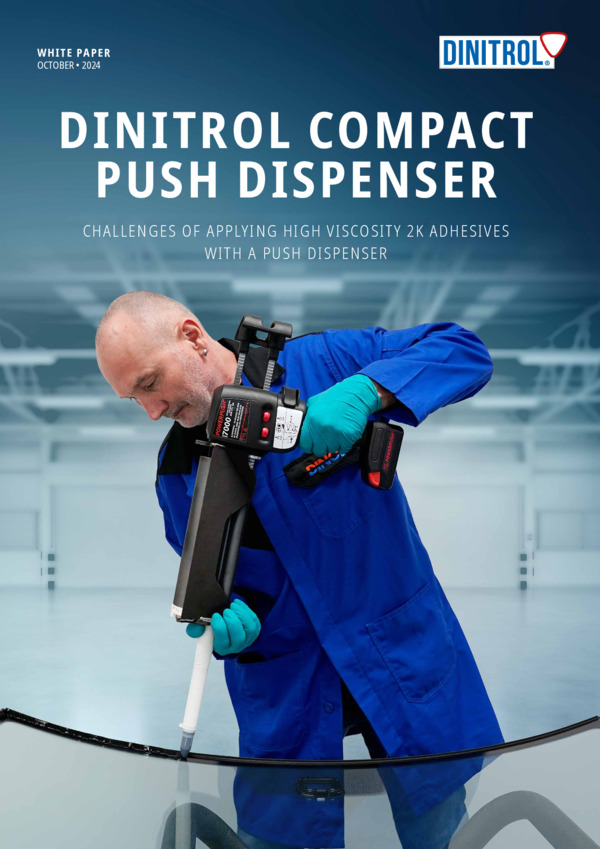

COMPACT PUSH DISPENSER

Flexible hand application of the future

The Compact Push Dispenser offers a modern solution for processing selected DINITROL adhesives.

Its compact design, easy handling, and sustainable packaging enable precise application while reducing material usage. Ideal for professional applications where quality and efficiency matter.

Technically engineered for maximum efficiency:

The DINITROL COMPACT PUSH DISPENSER was specifically developed for processing air-moisture-reactive DINITROL adhesives. By selectively adding a B component at a mixing ratio of 10:1, curing can be significantly accelerated while maintaining a high level of process reliability, as the adhesive also reacts reliably without the B component. The dispenser’s compact design allows for ergonomic handling and makes it ideal for industrial applications where precise dosing, efficiency, and material compatibility are required.

Areas of Application

Whether trucks, buses, rail vehicles, or agricultural machinery – DINITROL adhesive systems offer reliable solutions for a wide range of manufacturing and repair applications. From thick-layer bonding and direct glazing to surface bonding, they enable safe, low-emission, and efficient processes – manual or automated, moisture-independent, and ideal for modern production requirements.

DINITROL 516 A/B

Add-on Parts – Rail Bonding

Bonding of add-on parts and rails in vehicle construction places high demands on material performance and process reliability. With the 2-component system DINITROL 516 A/B, bonding and sealing can be efficiently combined in a single operation. The long open time of approximately 30 minutes allows for flexible processing, while rapid curing ensures the vehicle is ready to drive/durable after just 6 hours.

Thanks to its moisture-independent curing and high strength development, the system is ideal for large-area bonding with complex geometries. Its low-emission formulation is free from solvents, preventing CO₂ bubble formation and ensuring flawless results. OEM approvals confirm its suitability for professional use in both manufacturing and repair – delivering noticeable cycle time reduction and high process reliability.

Special Container Construction

In industrial container manufacturing, adhesive systems are required that meet high mechanical demands while also supporting process optimization. The 2-component system DINITROL 516 A/B offers a long open time of approximately 30 minutes and enables simultaneous bonding and sealing in a single step – ideal for reducing assembly times.

Its fast, moisture-independent curing ensures a defined strength build-up and allows further processing after just 6 hours. Even in large-area applications with high material usage, bubble-free application delivers reliable results without defects. The system is solvent-free and low in emissions – a cost-effective and safe solution for modern special container manufacturing processes.

Further Areas of Application

- Floor Panel Bonding

- Direct Glazing

- Front Mask and Side Wall Panel

- Thin-Layer and Surface Bonding

Benefits of the new system

- Very powerful, compact battery gun with relatively low weight – Approx. 4.39 kg

- Improved mixing – Full adhesive properties such as open time and increase in strength

- More capacity – fewer change processes – 638 ml now, 490 ml previously

- Increased shelf life – From 9 months to 12–18 months (depending on the adhesive)

- No packaging as a set – Fewer unnused components are thrown away

- Less waste compared to cartridges– The bag is completely squeezed out and therefore more environmentally friendly

- Fewer accessories required – Retaining ring and cartridge are no longer required

- High discharge rate – Approx. 300 ml/min at RT up to 600 ml/min at 30–35°C material temperature

- Short charging time (approx. 20 minutes) – 20 V battery, approx. 17 sets with one battery charge

Download

Rely on our expertise and high-quality products to enhance reliability and efficiency.

Our experienced team is here to help you select the best solutions tailored to your specific requirements.

Contact us today to learn more about our solution.

We collaborate with trusted distribution partners worldwide to make our products easily accessible. Explore our network of partners here.

Whether brochures, flyers, or product images – our download section provides all the essential information about our offerings for easy access and further use.

If you have any questions, we are happy to assist you. Our experts are ready to support you with your concerns and find a solution for your project.