PDI-Center

PDI centers (Pre-Delivery Inspection Centers) face the challenge of meeting the increasing customer requirements of OEMs. High-quality corrosion protection for vehicles is becoming increasingly important. Protecting vehicles during transport is also gaining significance. DINITROL offers specialized solutions to optimally protect cars, electric vehicles, and agricultural machinery, ensuring flawless quality control before delivery and before the vehicles are handed over to the end customer.

On-Page Navigation

Corrosion Protection

PDI centers face the challenge of optimally preparing imported vehicles, agricultural and construction machinery for delivery. A key aspect is transport protection to prevent corrosion on the way to the destination. DINITROL offers the ideal solution for this: a solvent-free, washable protection that prevents paint damage and makes the use of fabric garages unnecessary. This protects vehicles from salty air and flash rust while making possible transport damage immediately visible..

Especially for agricultural machinery with sensitive metal parts and aluminum alloys, DINITROL offers effective protection to ensure corrosion-free delivery to the customer.

Additionally, the requirements for vehicles from the end customer of OEMs are increasing.With the proven DINITROL corrosion protection solutions, PDI centers can offer their OEMs a valuable additional service, backed by approvals from leading manufacturers. This ensures that every vehicle can be delivered to the end customer in a corrosion-free condition. Especially in cold countries and European markets with stringent requirements for corrosion protection, DINITROL reliably meets the necessary standards for corrosion resistance.

Our solutions

Cavity Protection & Underbody Protection

After transport and before delivery to the customer, professional post-treatment of vehicles, electric cars, and agricultural machinery is an important service to ensure their quality and value retention. Targeted cavity protection and underbody coating ensure that hidden areas of the vehicle are optimally protected and that external influences—especially on new vehicles—are minimized.

By using modern protective products such as DINITROL 977, a water-based and environmentally friendly corrosion protection agent with excellent penetration properties, even hard-to-reach areas can be reliably sealed. The low-odour and non-sticky formulation allows for pleasant application in PDI-Centers and workshops, while the high-quality standard ensures long-term value retention. This additional treatment helps vehicles maintain their performance over the long term. In combination, DINITROL 958, an environmentally friendly, water-based stone chip protection, can also be applied. It is solvent-free and forms a black, elastic film after application, reliably protecting the vehicle from mechanical stresses.

DINITROL 3641 A is a solvent-based corrosion protection agent designed for use in cavities, underbody, and chassis of vehicles. It forms a soft, protective film with excellent creeping properties and high resistance to rust, making it ideal for long-term protection under demanding conditions.

DINITROL 620-85 GOLD is a solvent-based, bitumen-based coating for partial or complete underbody protection. It offers excellent adhesion, high flexibility even at low temperatures, and long-lasting durability. With excellent stone chip resistance and long-term corrosion protection, it is ideal for workshops and professional applications.

Our solutions

Stone Chip Protection

DINITROL 958 offers a reliable solution to effectively protect exposed parts such as door sills, spoilers, shock absorbers, wheel arches, and edges from the harmful effects of stone chipping and road salt.

The environmentally friendly water-based stone chip protection is solvent-free and forms a black, elastic film after application reliably protecting the vehicle from mechanical stresses. This protective film can be easily painted over with most automotive paints once dry, ensuring the vehicle’s aesthetic appearance is not affected. With DINITROL 958, every vehicle is optimally prepared and protected from costly damage before being handed over to the end customer.

Our solutions

Transport Protection

Without proper protection, metal parts can quickly rust throughout the entire logistics process, leading to significant damage and increased maintenance costs. This is especially true during international transport, such as by sea, where vehicles and machinery are exposed to harsh conditions and must be protected from salty air and flash rust.

DINITROL 970 offers the optimal solution for this. The environmentally friendly, water-based protective agent reliably shields attachments, spare parts, screw connections, and steel surfaces from corrosion. Its fast-drying, waxy protective layer forms a transparent film that becomes resistant to rainwater after just 50 minutes, ensuring long-term protection.

Additionally, DINITROL provides an innovative alternative to conventional transport solutions like fabric garages, which can often cause paint damage. The washable, solvent-free protective layer eliminates the need for complex cover system installations, and any potential damage always remains visible.

Our solutions

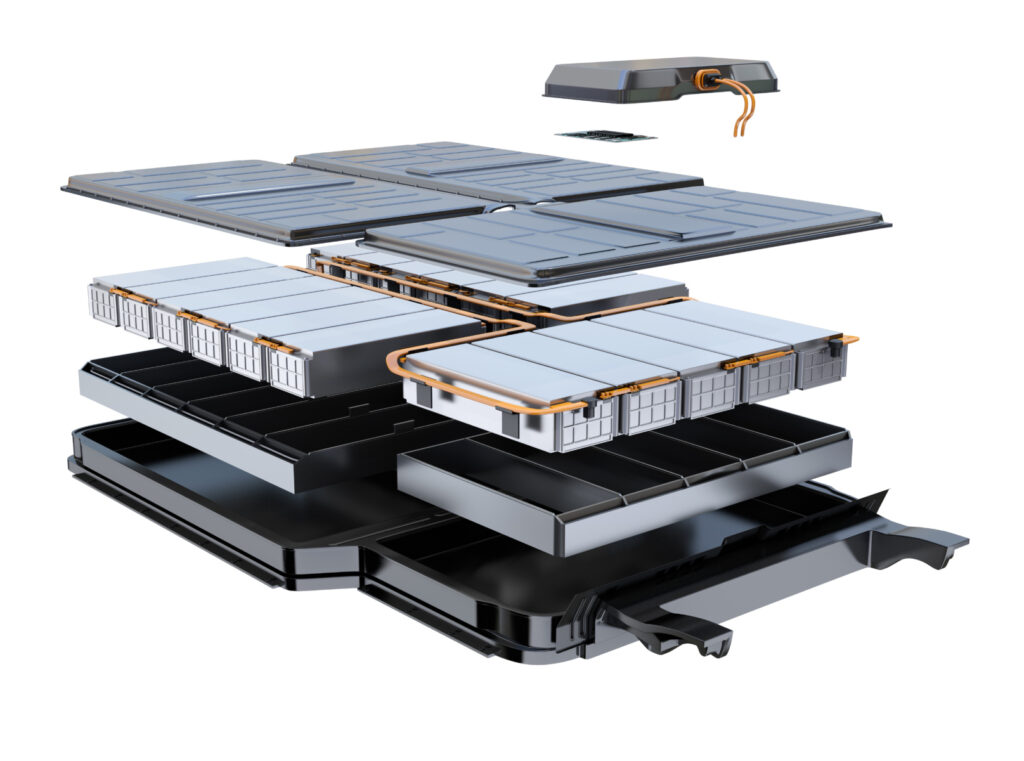

Long-term Corrosion Protection for Electric Car Batteries

High-quality protective solutions effectively prevent corrosion on electric vehicle batteries and contribute to long-term value retention. Preventive measures stop rust formation, extending the vehicle’s lifespan and enhancing safety. The battery’s temperature management remains unaffected, and performance is not compromised. Additionally, these protective solutions are tested for compatibility and are suitable for all parts of the battery, ensuring comprehensive corrosion protection.

These innovative products provide all-around protection for various areas of the vehicle and EV batteries:

- Battery cover/battery housing

- Seals, joints & screws

- Cavities & joints

- Underside of the battery housing & vehicle underbody

Adhesives & Sealants

After transport, final quality checks and adjustments are essential to ensure that vehicles are handed over to the customer in perfect condition. High-quality windshield adhesives enable efficient and durable repairs during replacement glazing.

Additionally, specially formulated primers and cleaning agents ensure optimal adhesion and processing, allowing vehicles to be repaired quickly and reliably.

Our solutions:

Replacement Glazing

Proper windshield bonding is essential in the PDI-Center. The high-modulus, one-component polyurethane windshield adhesive DINITROL 9100 is notable for its excellent processing characteristics. Vehicles can be moved just 30 minutes after the windshield is bonded, which is a significant time advantage for the PDI-Center.

Our solutions

Trust our expertise and high-quality products to increase reliability and effectiveness. Our experienced team is at your side to help you choose the best solutions for your specific requirements.

Contact us today to learn more about our solutions and optimally equip your vehicles..

We collaborate with trusted distribution partners worldwide to make our products easily accessible. Explore our network of partners here.

Whether brochures, flyers, or product images – our download section provides all the essential information about our offerings for easy access and further use.

If you have any questions, we are happy to assist you. Our experts are ready to support you with your concerns and find a solution for your project.